Views: 1376 Author: Site Editor Publish Time: 2025-10-29 Origin: Site

Data center energy consumption originates from IT equipment, lighting, air conditioning, and power distribution systems. Power supply reliability is crucial for data centers.

IT equipment, comprising servers, storage, and network communication devices, accounts for approximately 45% of the total data center power consumption.

Cooling systems, primarily used for dissipating heat from IT equipment, represent one of the largest sources of energy consumption and a key area for improving data center energy efficiency, constituting about 40% of power usage.

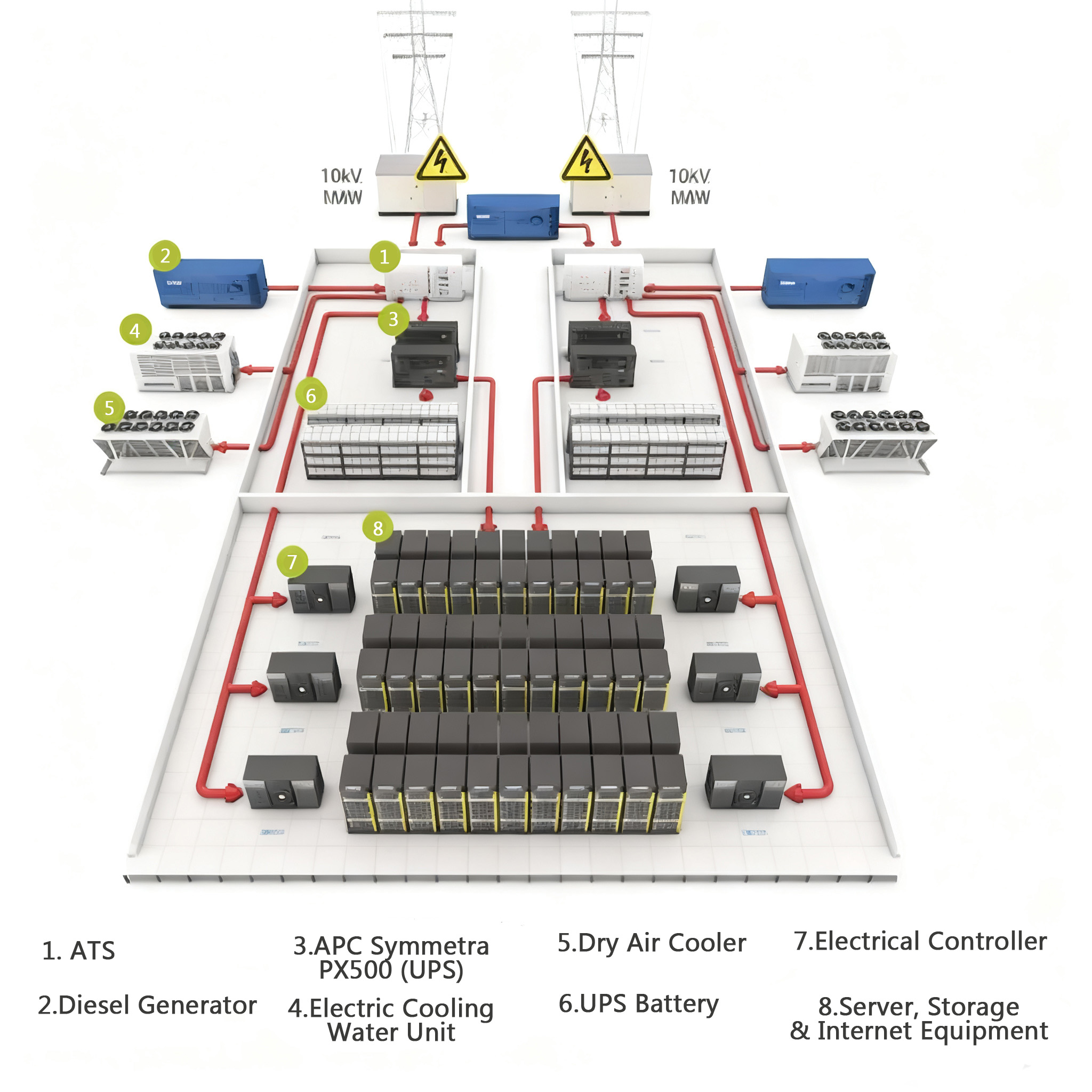

The power distribution system consists of input transformers, ATS (Automatic Transfer Switch) switches, UPS, and distribution cabinets, accounting for approximately 10% of power consumption. Within this, about 7% comes from the UPS and its output power distribution system, and 3% from the UPS input power supply system.

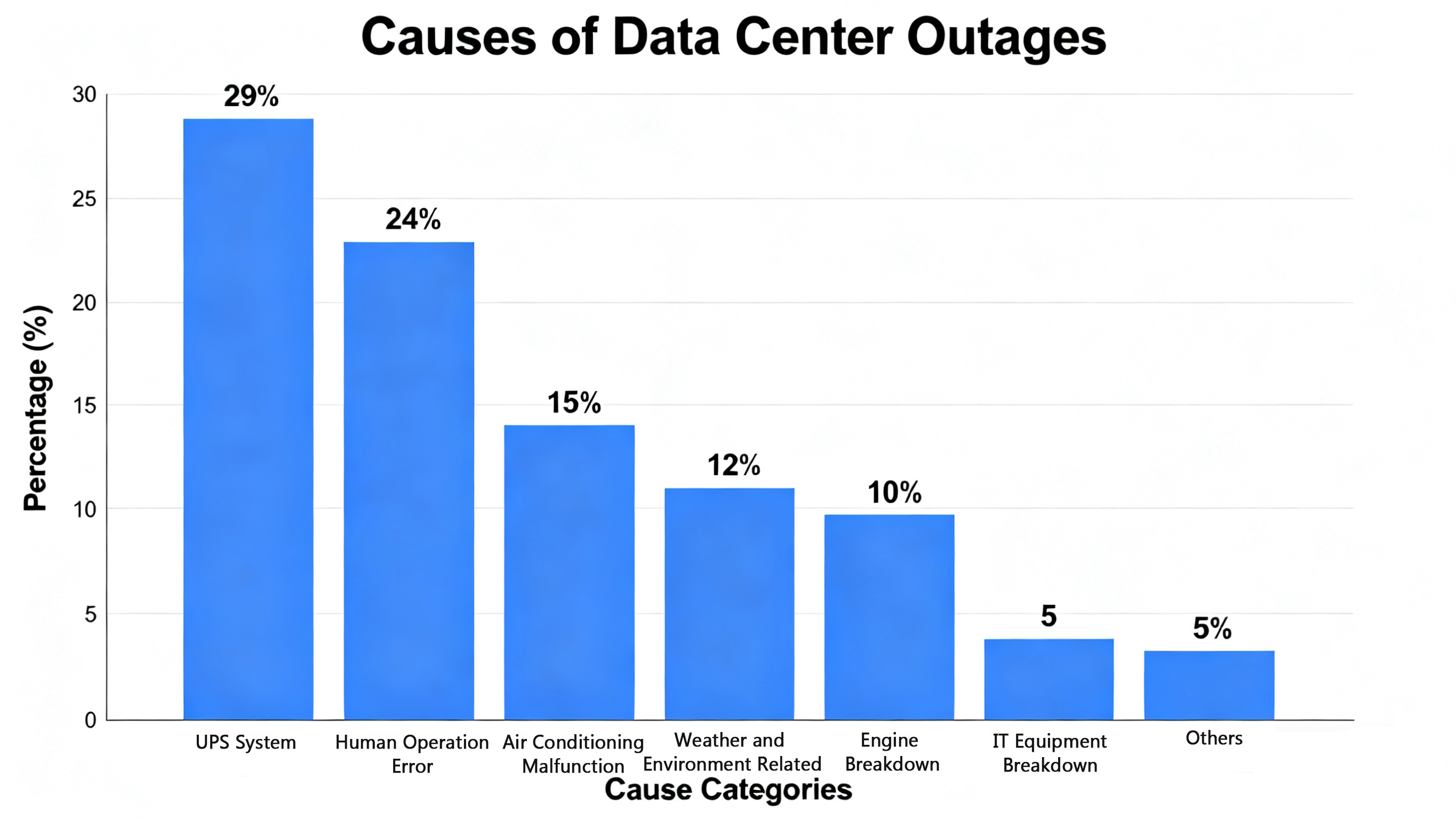

According to the "2022 Global Data Center Survey" report released by Uptime Institute, the global authority on digital infrastructure, over half (55%) of operators reported experiencing site outages in the past three years, with power distribution system-related issues accounting for 39% of these incidents. This underscores the critical importance of power system reliability for data centers.

The data center power distribution system converts high voltage to medium voltage, and then to low voltage for use by IT equipment. The utility provider supplies high voltage (>100kV) or medium voltage power, which requires an on-site substation and power transformers to step it down to medium voltage (MV). MV switchgear safely distributes the MV power to another transformer, located near the data hall, which reduces the voltage to low voltage (LV, e.g., 415V). Paired with this transformer is a diesel generator, which also outputs at 415V AC.

If the utility power fails, the Automatic Transfer Switch (ATS) automatically switches the load to the generator. From this point, two power paths emerge: one to the IT equipment and another to the cooling equipment. The IT equipment path first flows through the UPS system, which is connected to a battery bank typically providing 5-10 minutes of storage time – sufficient for the generator to start (within one minute) and avoid temporary outages. UPS power is typically supplied directly to IT equipment via Power Distribution Units (PDUs).

The final step involves delivering power to the chips via the Power Supply Unit (PSU) and Voltage Regulator Module (VRM).

In recent years, with the development of Artificial Intelligence (AI), machine learning, and big data analytics, the demand for computing resources has surged dramatically. Continuous iterations in CPU and GPU technology have driven significant improvements in computing power. For example:

The Thermal Design Power (TDP) of new-generation GPUs (such as NVIDIA's A100, H100, and subsequent Blackwell series) continues to increase, rising from several hundred watts to 700W, even exceeding 1200W.

As AI training and inference require extremely high computational capabilities, the number of GPUs deployed per data center has increased sharply, consequently driving up overall power demand.

Generators are matched one-to-one with low-voltage transformers to ensure data center operation during upstream power failures. A generator, with power output matched to the transformer, is installed beside each low-voltage transformer. These generators activate in case of a failure in the transformer or its upstream power source. If a main power failure occurs, the Automatic Transfer Switch (ATS) in the low-voltage switchgear automatically switches to the generator (each generator in a hyperscale campus typically has a power rating of 2-3 MW). A single 3MW generator has more than 4000 horsepower. Twenty or more such generators are commonly found in hyperscale data centers. For example: Cummins Power provided 45 C2500D5A diesel generator sets equipped with Cummins QSK60 engines for the Zhejiang Cloud Computing Data Center, and 24 C2500D5A-10.5KV units for an Alibaba project in Nantong.

Diesel generator set power capacity can reach up to 2 times the total IT load. According to CDCC, in one data center renovation case, there were 1376 x 4kW server cabinets and 24 x 4kW network cabinets. Considering a utilization factor of 0.9, the total IT load was 5040kW. This project used 5+1 units of 1800kV medium-voltage outdoor diesel generator sets. We observe that in this case, the diesel generator power is approximately twice the total IT load.

According to CDCC, the typical prices for mainstream diesel generator brands in the data center industry are approximately: 2.5 million RMB for 1800kW, 3.6 million RMB for 2000kW, 5.5 million RMB for 2200kW, and 8.3 million RMB for 2500kW (all at common power rating).

A simple sensitivity analysis shows that, assuming the use of 2000kW diesel generators and a requirement of twice the total IT load, the market size for diesel generators required for 25,000 racks of GB200 NVL72 is approximately 10.8 billion RMB.

The global data center diesel generator market size is expected to reach 55.5 billion RMB by 2025. According to SemiAnalysis, the CAGR for data center power capacity is expected to accelerate from 12-15% in the coming years to 25%.

Global data center critical IT power demand is projected to surge from 49GW in 2023 to 96GW in 2026, with AI consuming about 40GW. The new demand added over the three years from 2023-2026 is 47GW. We see that the growth is primarily driven by AI demand.

Assuming the use of 2000kW diesel generators and a requirement of twice the total IT load, the total combined market size for 2024, 2025, and 2026 is projected to be 169.2 billion RMB. Based on an average annual growth rate of 25%, the market sizes for 2024-2026 are estimated to be 44.4 billion, 55.5 billion, and 69.3 billion RMB, respectively.

According to CDCC, against the backdrop of the rapid rise of AIDC, data center scale has developed to the hyperscale campus level, further increasing the required diesel generator capacity and the number of paralleled units, placing higher demands on the performance and reliability of diesel generator equipment.

In the future, AIDCs will tend to favor high-power diesel generators. Meanwhile, in the short term, the supply of data center diesel generators cannot meet demand, and the industry is expected to experience both volume and price increases.

Overseas manufacturers dominate the data center diesel generator set industry. Data centers primarily use imported brands of diesel generator sets, mostly products from Cummins, Caterpillar, MTU, Mitsubishi, etc. Commonly used models include the Cummins C2500D5A, Caterpillar 3516B, and MTU 4000 series. Among the mainstream high-power, high-speed diesel engine brands in the market, besides imported brands, there are currently joint venture brands such as Yuchai MTU and Chongqing Cummins. Domestic brands like Yuchai, Weichai, and Pangu(Googol) already have some application cases in the data center market.

Category | Description | Requirement | Import Diesel Generator | Domestic Diesel Generator |

Diesel Generator Set | Data Center Continuous Power (Based on ISO-8528 DCP Power) | 1800-2400kw | ☆☆ | ☆☆ |

Altitude Range Without Capacity Reduction | 1500m | ☆☆ | ☆☆☆ | |

Ambient Temperature Range Without Capacity Reduction | -10~40℃ | ☆☆ | ☆☆☆ | |

Size | Whether it can be arranged in a 40-foot standard container | ☆☆☆ | ☆☆ | |

Weight (Net Weight) | - | ☆☆☆ | ☆☆ | |

Fuel Consumption (100% Load Rate) | ≤240g/kWh | ☆☆☆ | ☆☆ | |

Time from Start to Voltage Establishment | 6s | ☆☆☆ | ☆☆ | |

Time from Start to 100% Load | 60s | ☆☆☆ | ☆☆ | |

Load-Bearing Performance Level | G3 | ☆☆☆ | ☆☆☆ | |

Transient Load Capacity Under G3 | 0-50% | ☆☆☆ | ☆☆☆ | |

Can provide instantaneous transient load capacity 0-X% (X>50) | ||||

Transient Voltage Deviation | 100% step: ≤20%, 0-50% step: ≤15% | ☆☆☆ | ☆☆☆ | |

Transient Voltage Recovery Time | ≤4s | ☆☆☆ | ☆☆☆ | |

Transient Frequency Deviation | 100% step: ≤10%, 0-50% step: ≤7% | ☆☆☆ | ☆☆☆ | |

Transient Frequency Recovery Time | ≤3s | |||

Noise | ≤110dB | ☆☆☆ | ☆☆☆ | |

Vibration | Displacement <0.72mm, Vibration Speed <... (partially obscured) | |||

Capacitive Load Capacity | Capacitive -0.9 to 1 No Capacity Reduction | ☆☆☆ | ☆☆☆ |

Category | Description | Requirement | Import Diesel Generator | Domestic Diesel Generator |

Diesel Engine | Fuel Injection Method | Electronic Injection or High-Pressure Common Rail | ☆☆ | ☆☆ |

Engine Speed Control | Electronic Speed Control | ☆☆☆ | ☆☆☆ | |

Radiator Ambient Temperature | 40-45℃ | ☆☆ | ☆☆☆ | |

Starter Battery Capacity | At Least 6 Times | ☆☆☆ | ☆☆☆ | |

Charger | Pulse Charger | ☆☆☆ | ☆☆ | |

Fuel Cooler | Factory Configuration | ☆☆☆ | ☆☆ | |

Cylinder Water Heater | 9/12KW | ☆☆ | ☆☆ | |

Generator | Engine Oil | Factory Configuration | ☆☆☆ | ☆☆ |

Coolant | Factory Configuration | ☆☆☆ | ☆☆ | |

Excitation Method | PMG or AREP | ☆☆☆ | ☆☆☆ | |

AVR | Factory Equipped or BASLER DECS150 (BASLER DECS150) | ☆☆☆ | ☆☆☆ | |

Insulation Class | Not Lower Than F Class | ☆☆☆ | ☆☆☆ | |

Temperature Rise Class | Not Lower Than F Class | ☆☆☆ | ☆☆☆ | |

Bearing | Double Bearing | ☆☆ | ☆☆☆ | |

Efficiency | ≥95% | ☆☆☆ | ☆☆☆ | |

Temperature Sensor | Winding RTD6, Bearing RTD2 | ☆☆☆ | ☆☆☆ | |

Protection Class | Not Lower Than IP23 | ☆☆☆ | ☆☆☆ | |

Coupling and Vibration Isolator | Coupling and Vibration Isolator | High-Elastic Coupling, Flender Equivalent. Isolator, Factory Configured or Flender Equivalent. | ☆☆☆ | ☆☆ |

Parallel Controller | Control Panel Model and Function | Factory Configured or BASLER, DEIF etc. (BASLER, Danfoss Equivalent) | ☆☆☆ | ☆☆ |

Container | Size | 40ft Standard or Other Sizes | ☆☆ | ☆☆ |

Noise Level | 75dB | ☆☆ | ☆☆ | |

Weight (Including Diesel Engine and Matching Equipment) | - | ☆☆☆ | ☆☆ |

Power selection must be based on actual operating conditions. The power selection of diesel generator sets has a very significant impact on data center investment and power supply guarantee. Different customers choose appropriate generator set power based on different needs, offering considerable flexibility.

As important standards for diesel generator sets, ISO 8528-1 and GB/T 2820-1 define four types of diesel generator set power ratings. However, as the defined power ratings are based on four operating conditions that do not fully align with the load profile of data centers, owners need to select based on the characteristics of the data center.

Cummins Power took the lead in the industry by proposing DCC (Data Center Continuous) power, a continuous power supply rating suitable for data center use, tailored to the operational characteristics of data centers. This provides significant value for data center investment and operational management. The DCC rating is recognized by Uptime Institute and can be used for Uptime Tier III and Tier IV certification.

The engine provides the necessary power for the diesel generator set. Engine selection is the most critical part of choosing a generator set.

Provide sufficient power and dynamic response to load changes. Due to the complexity of designing and manufacturing large-capacity diesel engines, engines from different manufacturers can vary significantly. The engine's ability to provide sufficient power is a primary consideration, followed by its dynamic response to load changes, which is also an important technical indicator.

With technological advancements, the main trend in diesel engine development is towards smaller displacement and higher power. Manufacturers are striving to increase engine power density through various means. Traditional diesel engines had very low power density; for example, naturally aspirated engines had power output directly proportional to their displacement, but such models are largely obsolete internationally. With the development of turbocharging technology and the maturity of high-pressure clean combustion technology, the power density of diesel engines offered by manufacturers worldwide is continuously improving. Measures to increase power density include increasing air charge, improving mechanical efficiency, and enhancing combustion efficiency.

1. Meet the required output power.

2. Possess good dynamic characteristics: capability for single-step full load acceptance.

3. Electronic fuel injection (EFI) engine – EFI engines offer superior load acceptance characteristics.

4. Have proven application experience and a large number of application cases.

Data center IT equipment, UPS loads, and variable frequency drives (VFDs) for chillers exhibit significant harmonic characteristics. Different types of rectifier equipment also have different harmonic signatures. Harmonic loads can greatly impact the power quality of the electrical system. They may cause abnormal operation of equipment, such as overheating of motors and transformers, unusual noise and vibration, and cable overheating. Therefore, the impact of connected harmonic loads must be assessed to prevent system abnormalities caused by harmonics. The national standard GB/T 14549 "Power Quality - Harmonics in Public Supply Network" specifies the limits for harmonic voltage distortion allowed at various grid levels.

Assessing the impact of harmonics requires understanding the harmonic current content (THDI) of all harmonic-producing equipment, and then calculating the harmonic voltage distortion rate it causes in the system based on the subtransient impedance of the standby diesel generator set. In summary, when selecting a diesel generator set, besides verifying the engine power based on the load size, the impact of harmonic currents must also be calculated considering the magnitude of the harmonic load.

In current data center IT equipment power supply systems, the presence of capacitive loads in electrical equipment causes the system's load characteristics to exhibit leading power factor operation. This imposes higher technical management requirements on the corresponding power supply system. Capacitive loads pose two significant hazards in the power supply system: resonant overvoltage during generator set light loads and potential system instability during full load.

Power supply systems strictly prevent operation at a leading power factor. The power industry has clear regulations for reactive power management: it requires power users to prevent the reverse flow of reactive power into the grid, and also requires generators to have a certain capacity to absorb reactive power, in order to consume the reactive power generated by the grid itself.

The backup power system for data centers primarily consists of UPS and diesel generator sets. Static UPS with batteries provides uninterrupted power supply to the data center, while diesel generator sets can continue to provide continuous power supply after the brief power support from the UPS. The coordination between them is very important. Besides considering harmonic compatibility and capacity selection, timing coordination should also be considered. If the diesel generator set can be brought online quickly, it can significantly reduce the investment in static UPS batteries and reduce the footprint required for batteries. Since batteries also require regular maintenance and replacement, shortening the diesel generator set's start-up and power availability time is very meaningful.

When multiple diesel generator sets start, paralleling onto the busbar is not allowed without synchronization when the busbar is de-energized. The Cummins Power First Start Sensor module can automatically detect the first unit to reach rated conditions after multiple diesel generator sets start simultaneously, connect it to the system busbar, and prevent other units from closing. After the first unit is successfully connected, other units synchronize and parallel with the busbar, achieving the shortest system paralleling time and optimal closing reliability.

Regardless of the starting method used, rapidly completing the energization of the busbar by the diesel generator set and achieving paralleling are the most critical elements.

In high-voltage diesel generator set systems, to reduce the harm of single-phase ground fault current to system equipment and the risk of injury to personnel from fault arcs, the neutral point of high-voltage sets is grounded through a small resistance. The design of the grounding resistor must consider both meeting system protection requirements, ensuring that the ground protection device operates during a single-phase ground fault, and avoiding the hazards of excessive ground fault current. Typically, the ground fault current is controlled between 100~1000A, with a typical value of 400A. There are several methods for neutral grounding: one resistor per unit, a common resistor for all units, or a common small resistance via a grounding transformer on the busbar. The choice of grounding method depends on the specific project circumstances.

To ensure the stable operation of the diesel generator set,the ventilation of engine room is crucial. The engine room must ensure sufficient air circulation to remove heat, smoke, and exhaust gases produced by the engine, generator, and ancillary equipment, and to provide combustion air.

The cooling methods for generator sets are divided into radiator-coupled cooling and remote heat exchanger cooling. Regardless of the method, it is essential to ensure adequate ventilation in the engine room so that the heat generated by the unit can be removed promptly, preventing unit malfunction due to high temperatures. The air outlet should be positioned appropriately to ensure air flows from the generator end past the engine, carrying away radiant heat from the engine surface. Meeting the equipment's specified ventilation rate is key in ventilation design. Calculating the required ventilation rate must consider the resistance generated by various parts of the ventilation duct; this resistance value must not exceed the limit specified by the equipment.

The capacity and type of fuel tank equipped with the unit are determined by product technical specifications and must also comply with national fire safety codes based on the installation location.

Fuel tanks must be made of high-quality steel plate, require buried corrosion protection treatment, and be equipped with level gauges. Each underground tank should contain a continuous magnetic float level gauge capable of outputting a 4-20mA signal to the PLC controller.

The day tank must be equipped with a manhole cover, fuel inlet pipe, return pipe, drain pipe, overflow pipe, level gauge, etc. It must use an industrial-grade magnetic level gauge with marker, clearly marked with fuel height, featuring local display and capable of providing a remote 4-20mA signal.

Two fuel transfer pumps shall be installed. Each pump must be capable of transferring light diesel oil with sufficient flow rate to ensure full load operation of the generator sets. Fuel transfer pumps shall be supplied with all necessary accessories, including filters, check valves, etc. The pump motors shall be explosion-proof design, 3-phase, 50Hz, with overload protection.

The control system must include monitoring for the underground tank level and day tank level, control solenoid valves and transfer pumps, and provide corresponding alarm information. It shall allow standard Modbus-RS485 signals for integration with the Building Management System (BMS).

Load bank testing for diesel generator sets is highly significant. During project acceptance, load bank testing can verify whether the unit can achieve full load power output and check if the ventilation, exhaust, fuel supply, and electrical system design and installation meet the design requirements. Simultaneously, during routine maintenance, it provides loaded operation for the engine, preventing potential issues like carbon buildup that can result from prolonged light-load operation, thereby ensuring the reliable operation of the generator set.